Introduction to Crimping Quality Importance The quality of crimping is critical in ensuring secure, durable, a...

Rebar Cutter Blade

Ordinary Accessories For Hydraulic Tools

-

Product information

A rebar cutter blade is a specialized hydraulic attachment designed for the cutting of steel rebar, which is commonly used in the construction industry for reinforced concrete structures. These blades are engineered to provide clean, precise cuts through the hard steel material, ensuring the rebar is prepared correctly for use in various construction applications.

Rebar cutter blades are typically mounted on hydraulic excavators, skid steer loaders, or other heavy machinery to leverage the power and precision needed for cutting rebar. They are designed to withstand the high tensile strength of steel and to deliver consistent, accurate cuts.

Design and Construction

1. Material: Rebar cutter blades are made from high-quality, wear-resistant steel alloys to ensure durability and longevity.

2. Design: The design of the blade includes sharp, hardened steel cutting edges that are shaped to shear through the rebar with minimal effort.

3. Hydraulic Power: The hydraulic system provides the necessary force to drive the cutting action, allowing for quick and efficient cutting.

Types of Rebar Cutter Blades

1. Fixed Blade: These have a fixed cutting edge and are suitable for straight cuts.

2. Adjustable Blade: These allow for cutting at different angles, providing more flexibility in cutting rebar to specific lengths.

3. Cutting Wheel: Some rebar cutters use a circular blade that spins at high speeds to cut through the rebar.

Features and Benefits

1. Efficiency: Hydraulic rebar cutter blades offer a fast and efficient way to cut rebar, saving time and labor costs.

2. Precision: The hydraulic pressure ensures a clean, precise cut, which is crucial for the structural integrity of the final product.

3. Safety: Using a hydraulic cutter reduces the risk of accidents associated with manual cutting methods.

4. Versatility: Many rebar cutter blades can handle a range of rebar sizes and types, increasing their utility on the job site.

Operation and Maintenance

1. Operation: The operator controls the hydraulic flow to the cutter blade, which is attached to the machine's arm. The blade is positioned against the rebar, and the hydraulic pressure is applied to make the cut.

2. Maintenance: Regular maintenance is essential to ensure the longevity and performance of the blade. This includes checking for wear, sharpening the cutting edges, and lubricating the moving parts.

Safety Considerations

1. Training: Operators should be properly trained in the use of hydraulic rebar cutter blades to ensure safe and effective operation.

2. Safety Gear: Wearing appropriate safety gear, such as gloves, safety glasses, and hearing protection, is crucial.

3. Inspection: Before each use, the cutter blade should be inspected for any signs of damage or wear that could compromise safety or performance.

Applications

1. Construction: Rebar cutter blades are used extensively in the construction of buildings, bridges, and other infrastructure projects.

2. Fabrication Shops: They are also used in fabrication shops for cutting rebar to specific lengths for custom projects.

3. Disaster Recovery: In situations where damaged rebar needs to be removed or cut, these blades can be invaluable.

Rebar cutter blades are a critical component in the construction and manufacturing sectors, providing a means to efficiently and safely cut through one of the most widely used materials in reinforced concrete structures. Their design, operation, and maintenance are all focused on delivering a tool that can withstand the rigors of industrial use while ensuring the highest standards of safety and precision. As construction techniques and materials continue to evolve, the rebar cutter blade remains a versatile and indispensable tool in the industry.

Related products

Xinpu Tools Profile

Taizhou Xinpu Tools Co., Ltd. is a manufacturer specializing in the research, development, production, and sales of power transmission and distribution construction tools and hydraulic tools. Products serve the electric power, communications, transportation, petrochemical, mining, metallurgy, shipbuilding, and other industries.

Xinpu as a professional wholesale Rebar Cutter Blade supplier and custom Rebar Cutter Blade company with more than 20 years of experience, Our main products include various types of copper and aluminum terminal crimping tools, hydraulic pumps, cutting tools, multi-functional busbar processing machines, pipe bending machines, punching machines, copper bar cutting tools, copper bar bending tools, jacks, hydraulic pullers, Hydraulic hole opener, cable cutter, nut cutter, cold press pliers and a series of tools.

The company has advanced high-precision equipment in the industry, adopts technologies from advanced countries such as Europe, America, and Japan, and continuously launches high-quality, high-tech new products, which have been well received by users.

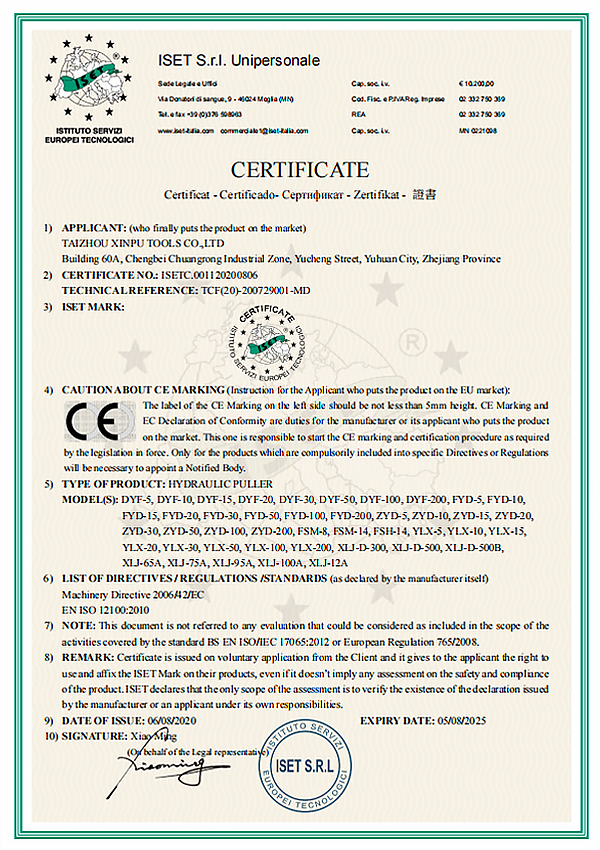

Our factory has passed the international CE system certification and ISO9001 quality management system certification. Guided by market demand, our products are constantly updated and improved. In line with the corporate purpose of "High quality and high credibility", we sincerely welcome new and old customers at home and abroad to call us. Letter to discuss business.

-

EP-430 integral hydraulic crimping pliers copper aluminum wire terminal crimping pliers 50-400mm ² safety valve protection

EP-430 integral hydraulic crimping pliers copper aluminum wire terminal crimping pliers 50-400mm ² safety valve protectionIntroduction to Compatibility with Different Dies A Hydraulic Crimping Tool is a powerful and efficient device...

-

CWC-150V split hydraulic cutting machine for copper, aluminum, and iron plates requires a pump for use

CWC-150V split hydraulic cutting machine for copper, aluminum, and iron plates requires a pump for useImportance of Hydraulic System Maintenance The hydraulic system is the core component of a Hydraulic Angle Ste...

Español

Español русский

русский