Introduction to Crimping Quality Importance The quality of crimping is critical in ensuring secure, durable, a...

Compression Tool Die

Ordinary Accessories For Hydraulic Tools

-

Product information

Compression Tool Dies, also known as compression molding dies, are essential tools used in the manufacturing industry for shaping and forming materials, particularly plastics and composites, into complex shapes and designs. These dies are used in conjunction with compression molding machines to produce a wide range of products, from simple buttons to intricate electrical components.

Introduction to Compression Tool Dies

Compression tool dies are precision-engineered to create a negative image of the desired part. They are typically made from high-quality steel or other durable materials to withstand the high pressures exerted during the compression molding process. The design of these dies is critical, as it directly affects the quality, accuracy, and detail of the final product.

How Compression Tool Dies Work

In a compression molding process, the material (usually in the form of a preheated pellet or sheet) is placed into the lower half of the die. The upper half of the die, known as the punch, is then forced down onto the material with great force. The heat and pressure applied cause the material to flow and take the shape of the die cavity. Once the material has cooled and solidified, the die opens, and the finished part is ejected.

Importance in Manufacturing

1. Precision and Detail: Compression tool dies allow for the creation of parts with intricate details and complex geometries that are difficult or impossible to achieve through other methods.

2. Material Efficiency: By applying pressure uniformly, these dies minimize material waste and ensure that the material is used efficiently to create the desired part.

3. Consistency and Repeatability: The use of compression tool dies ensures that each part produced is identical to the last, which is crucial for quality control and product consistency.

4. Strength and Durability: The high pressures used in compression molding result in parts with excellent structural integrity and durability.

5. Cost-Effectiveness: While the initial cost of tooling can be high, the long-term savings in material and production time often make compression molding a cost-effective choice.

Compression tool dies are used across various industries for a multitude of applications:

1. Automotive: For making electrical components, housings, and other parts that require precision and strength.

2. Aerospace: To produce high-strength components that can withstand extreme conditions.

3. Electronics: For creating insulators, connectors, and other components that need to be both strong and precise.

4. Medical: To manufacture parts that must be sterile and have a high degree of accuracy, such as components for prosthetics and surgical instruments.

5. Consumer Goods: For the production of a wide range of products, from appliance parts to toys.

Proper maintenance of compression tool dies is essential to ensure their longevity and the quality of the parts they produce. This includes regular cleaning to remove any residue, sharpening of edges, and repairing or replacing parts that show signs of wear.

Compression tool dies play a vital role in the manufacturing industry, enabling the production of high-quality, precision parts with a high degree of consistency. Their importance cannot be overstated, as they are the backbone of many mass production processes. As materials and technologies continue to evolve, so too will the capabilities and designs of compression tool dies, ensuring their continued relevance and importance in the production of goods across a wide range of industries.

Related products

Xinpu Tools Profile

Taizhou Xinpu Tools Co., Ltd. is a manufacturer specializing in the research, development, production, and sales of power transmission and distribution construction tools and hydraulic tools. Products serve the electric power, communications, transportation, petrochemical, mining, metallurgy, shipbuilding, and other industries.

Xinpu as a professional wholesale Compression Tool Die supplier and custom Compression Tool Die company with more than 20 years of experience, Our main products include various types of copper and aluminum terminal crimping tools, hydraulic pumps, cutting tools, multi-functional busbar processing machines, pipe bending machines, punching machines, copper bar cutting tools, copper bar bending tools, jacks, hydraulic pullers, Hydraulic hole opener, cable cutter, nut cutter, cold press pliers and a series of tools.

The company has advanced high-precision equipment in the industry, adopts technologies from advanced countries such as Europe, America, and Japan, and continuously launches high-quality, high-tech new products, which have been well received by users.

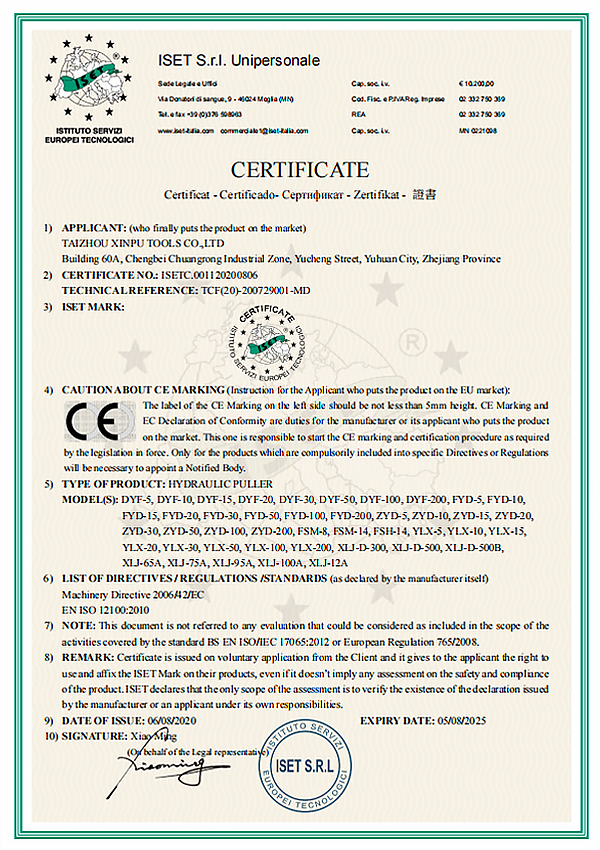

Our factory has passed the international CE system certification and ISO9001 quality management system certification. Guided by market demand, our products are constantly updated and improved. In line with the corporate purpose of "High quality and high credibility", we sincerely welcome new and old customers at home and abroad to call us. Letter to discuss business.

-

EP-430 integral hydraulic crimping pliers copper aluminum wire terminal crimping pliers 50-400mm ² safety valve protection

EP-430 integral hydraulic crimping pliers copper aluminum wire terminal crimping pliers 50-400mm ² safety valve protectionIntroduction to Compatibility with Different Dies A Hydraulic Crimping Tool is a powerful and efficient device...

-

CWC-150V split hydraulic cutting machine for copper, aluminum, and iron plates requires a pump for use

CWC-150V split hydraulic cutting machine for copper, aluminum, and iron plates requires a pump for useImportance of Hydraulic System Maintenance The hydraulic system is the core component of a Hydraulic Angle Ste...

Español

Español русский

русский