Introduction to Crimping Quality Importance The quality of crimping is critical in ensuring secure, durable, a...

Various Sizes of Oil Seal O-Rings Rubber Sealing Ring

Ordinary Accessories For Hydraulic Tools

-

Product information

Oil seal O-rings, also known as rubber sealing rings, are essential components in hydraulic systems, playing a crucial role in preventing fluid leakage and maintaining system integrity.

1. Functionality

Oil seal O-rings are designed to provide a reliable seal between mating surfaces in hydraulic components, preventing the leakage of hydraulic fluid under pressure. They achieve this by forming a tight and resilient seal around the circumference of shafts, pistons, valves, and other moving parts within hydraulic equipment. This sealing action helps to contain hydraulic fluid within the system, ensuring proper operation and preventing contamination or loss of fluid.

2. Construction and Materials

Oil seal O-rings are typically made from synthetic rubber materials such as nitrile rubber (NBR), silicone rubber (VMQ), fluorocarbon rubber (FKM), or ethylene propylene diene monomer (EPDM). These materials offer excellent resistance to hydraulic fluids, high temperatures, and wear, ensuring long-lasting performance in demanding operating conditions. The O-rings are precision-molded to exact specifications, ensuring a precise fit and reliable sealing capability.

3. Importance in Hydraulic Accessories

Oil seal O-rings are integral components in various hydraulic accessories, including:

Pumps and Motors: O-rings seal the interface between pump and motor housings, preventing fluid leakage and maintaining hydraulic pressure for efficient operation.

Valves and Manifolds: O-rings provide a leak-tight seal between valve components and manifold ports, ensuring proper flow control and system functionality.

Cylinders and Pistons: O-rings seal the gaps between cylinder walls and piston heads, preventing fluid bypass and ensuring smooth and reliable operation of hydraulic cylinders.

Fittings and Connectors: O-rings seal the threaded or flanged connections between hydraulic fittings, hoses, and connectors, preventing fluid leakage at junction points.

4. Importance of Various Sizes

The availability of oil seal O-rings in various sizes is crucial for accommodating the diverse range of hydraulic components and system configurations encountered in different applications. Hydraulic systems may comprise components of varying diameters, thicknesses, and geometries, necessitating O-rings of different sizes to achieve proper sealing and fit. Having a comprehensive range of O-ring sizes ensures compatibility with a wide range of hydraulic equipment, facilitating maintenance, repair, and replacement tasks.

5. Performance and Reliability

The performance and reliability of hydraulic systems depend on the effectiveness of O-ring seals in preventing fluid leakage and maintaining system integrity. Properly selected and correctly installed O-rings ensure leak-free operation, minimizing the risk of system downtime, fluid loss, and environmental contamination. High-quality O-rings with precise dimensions and compatible materials offer superior sealing performance, enhancing the efficiency and longevity of hydraulic equipment.

6. Maintenance and Replacement

Regular inspection, maintenance, and replacement of oil seal O-rings are essential for ensuring the continued performance and reliability of hydraulic systems. Over time, O-rings may degrade due to exposure to hydraulic fluids, temperature fluctuations, and mechanical wear, leading to loss of sealing effectiveness. Timely replacement of worn or damaged O-rings helps prevent fluid leaks, system malfunctions, and potential equipment damage, prolonging the service life of hydraulic accessories and reducing maintenance costs.

In conclusion, oil seal O-rings play a critical role in hydraulic systems by providing leak-tight seals between mating surfaces in hydraulic accessories. Their importance lies in preventing fluid leakage, maintaining system integrity, ensuring proper operation, and minimizing downtime and maintenance costs. Available in various sizes and materials, O-rings cater to the diverse needs of hydraulic applications, offering compatibility, reliability, and performance across a wide range of hydraulic equipment and systems. As integral components in hydraulic accessories, oil seal O-rings contribute to the efficiency, reliability, and longevity of hydraulic systems in industrial, automotive, aerospace, and other applications.

Related products

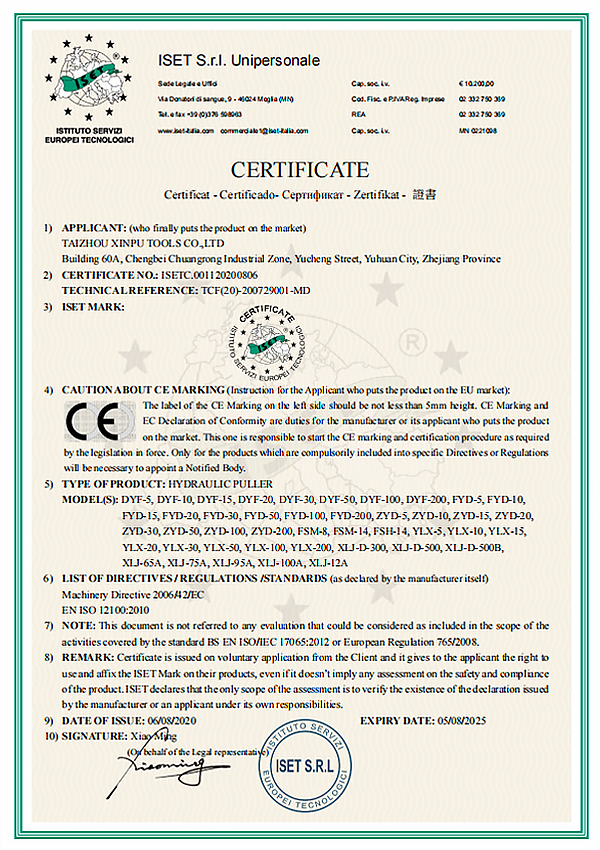

Xinpu Tools Profile

Taizhou Xinpu Tools Co., Ltd. is a manufacturer specializing in the research, development, production, and sales of power transmission and distribution construction tools and hydraulic tools. Products serve the electric power, communications, transportation, petrochemical, mining, metallurgy, shipbuilding, and other industries.

Xinpu as a professional wholesale Various Sizes of Oil Seal O-Rings Rubber Sealing Ring supplier and custom Various Sizes of Oil Seal O-Rings Rubber Sealing Ring company with more than 20 years of experience, Our main products include various types of copper and aluminum terminal crimping tools, hydraulic pumps, cutting tools, multi-functional busbar processing machines, pipe bending machines, punching machines, copper bar cutting tools, copper bar bending tools, jacks, hydraulic pullers, Hydraulic hole opener, cable cutter, nut cutter, cold press pliers and a series of tools.

The company has advanced high-precision equipment in the industry, adopts technologies from advanced countries such as Europe, America, and Japan, and continuously launches high-quality, high-tech new products, which have been well received by users.

Our factory has passed the international CE system certification and ISO9001 quality management system certification. Guided by market demand, our products are constantly updated and improved. In line with the corporate purpose of "High quality and high credibility", we sincerely welcome new and old customers at home and abroad to call us. Letter to discuss business.

-

EP-430 integral hydraulic crimping pliers copper aluminum wire terminal crimping pliers 50-400mm ² safety valve protection

EP-430 integral hydraulic crimping pliers copper aluminum wire terminal crimping pliers 50-400mm ² safety valve protectionIntroduction to Compatibility with Different Dies A Hydraulic Crimping Tool is a powerful and efficient device...

-

CWC-150V split hydraulic cutting machine for copper, aluminum, and iron plates requires a pump for use

CWC-150V split hydraulic cutting machine for copper, aluminum, and iron plates requires a pump for useImportance of Hydraulic System Maintenance The hydraulic system is the core component of a Hydraulic Angle Ste...

Español

Español русский

русский