Introduction to Crimping Quality Importance The quality of crimping is critical in ensuring secure, durable, a...

Press Tool Die

Ordinary Accessories For Hydraulic Tools

-

Product information

Press tool dies, also known as stamping dies, are critical components in the manufacturing industry, particularly for the production of automotive, aerospace, and various consumer goods. They are used in press operations to shape, cut, or form metal or other materials into desired shapes and sizes through the application of pressure.

Types of Press Tool Dies

1. Piercing Dies: Used to create holes in sheet metal by forcing a punch through the material, which is held on a die.

2. Blanking Dies: Designed to cut out shapes from sheet metal, leaving a clean, flat edge around the cutout.

3. Bending Dies: Shape metal by bending it along a straight line, which is crucial for creating corners and edges in parts.

4. Drawing Dies: Used in deep drawing processes to form a hollow part by pulling the material over a die.

5. Progressive Dies: These are complex, multi-stage dies that perform multiple operations in a single press stroke, increasing efficiency and reducing costs.

6. Compound Dies: Combine shearing and bending operations in a single press stroke.

Functions of Press Tool Dies

1. Shaping: Dies shape materials by applying pressure to create complex geometries.

2. Cutting: They can cut through materials cleanly and accurately.

3. Forming: Dies are used to form materials into specific shapes, such as automotive body panels.

4. Piercing: Creating holes in materials without causing deformation.

5. Trimming: Removing excess material to achieve precise dimensions.

Design and Material Considerations

1. Material: Dies are typically made from high-quality steel or other durable materials to withstand the high pressures and wear.

2. Design: The design must be precise to ensure the final product meets the required specifications.

3. Coatings: Some dies may have coatings to reduce friction, increase durability, or provide other benefits.

Manufacturing Process

1. CNC Machining: Computer Numerical Control (CNC) machines are often used to create the intricate details of a die.

2. Heat Treatment: Dies may undergo heat treatment to improve their hardness and durability.

3. Grinding and Polishing: To achieve the required surface finish and tolerances.

4. Assembly: Individual components of a die set are assembled with precision to ensure proper alignment and function.

Importance in Manufacturing

1. Efficiency: Press tool dies enable high-speed production with minimal manual intervention.

2. Quality: They ensure consistent quality across all produced parts.

3. Cost-Effectiveness: By automating the shaping process, dies reduce labor costs and material waste.

4. Safety: The use of dies in automated presses reduces the risk of injury associated with manual metalworking.

5. Customization: Dies can be customized for specific applications, allowing for a wide range of products to be manufactured.

Maintenance and Care

1. Regular Inspection: To ensure the die is functioning correctly and to detect any signs of wear.

2. Cleaning: Removing debris and lubricating can prolong the life of a die.

3. Replacement: Worn or damaged dies should be replaced to maintain production quality.

Press tool dies are indispensable in modern manufacturing, offering a precise and efficient way to shape and form materials. Their design and maintenance are critical to the production of high-quality parts, and their proper use is essential for the safety and productivity of the manufacturing process. As technology advances, the capabilities of press tool dies continue to evolve, meeting the demands of increasingly complex and high-precision industrial applications.

Related products

Xinpu Tools Profile

Taizhou Xinpu Tools Co., Ltd. is a manufacturer specializing in the research, development, production, and sales of power transmission and distribution construction tools and hydraulic tools. Products serve the electric power, communications, transportation, petrochemical, mining, metallurgy, shipbuilding, and other industries.

Xinpu as a professional wholesale Press Tool Die supplier and custom Press Tool Die company with more than 20 years of experience, Our main products include various types of copper and aluminum terminal crimping tools, hydraulic pumps, cutting tools, multi-functional busbar processing machines, pipe bending machines, punching machines, copper bar cutting tools, copper bar bending tools, jacks, hydraulic pullers, Hydraulic hole opener, cable cutter, nut cutter, cold press pliers and a series of tools.

The company has advanced high-precision equipment in the industry, adopts technologies from advanced countries such as Europe, America, and Japan, and continuously launches high-quality, high-tech new products, which have been well received by users.

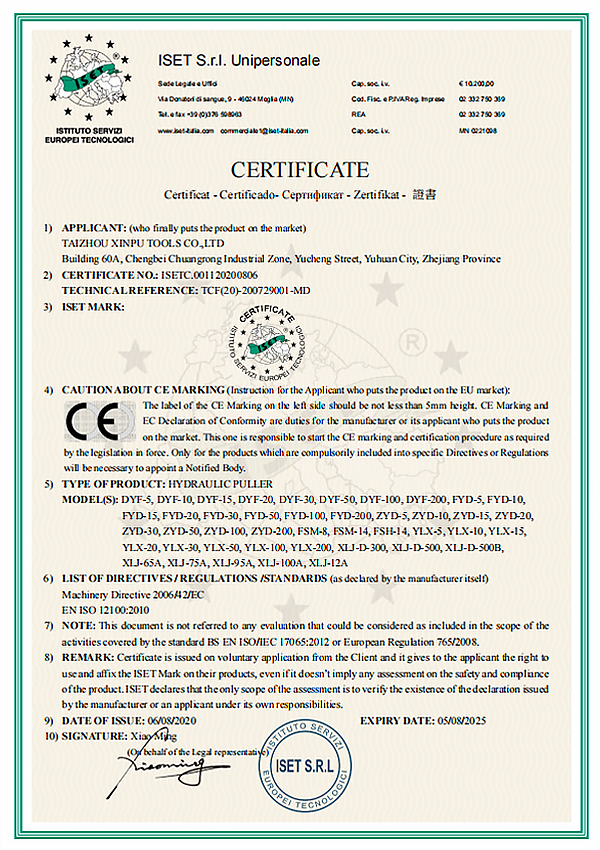

Our factory has passed the international CE system certification and ISO9001 quality management system certification. Guided by market demand, our products are constantly updated and improved. In line with the corporate purpose of "High quality and high credibility", we sincerely welcome new and old customers at home and abroad to call us. Letter to discuss business.

-

EP-430 integral hydraulic crimping pliers copper aluminum wire terminal crimping pliers 50-400mm ² safety valve protection

EP-430 integral hydraulic crimping pliers copper aluminum wire terminal crimping pliers 50-400mm ² safety valve protectionIntroduction to Compatibility with Different Dies A Hydraulic Crimping Tool is a powerful and efficient device...

-

CWC-150V split hydraulic cutting machine for copper, aluminum, and iron plates requires a pump for use

CWC-150V split hydraulic cutting machine for copper, aluminum, and iron plates requires a pump for useImportance of Hydraulic System Maintenance The hydraulic system is the core component of a Hydraulic Angle Ste...

Español

Español русский

русский