Comparative analysis of battery hydraulic pump and traditional hydraulic pump

2024.07.19

2024.07.19

Industry News

Industry News

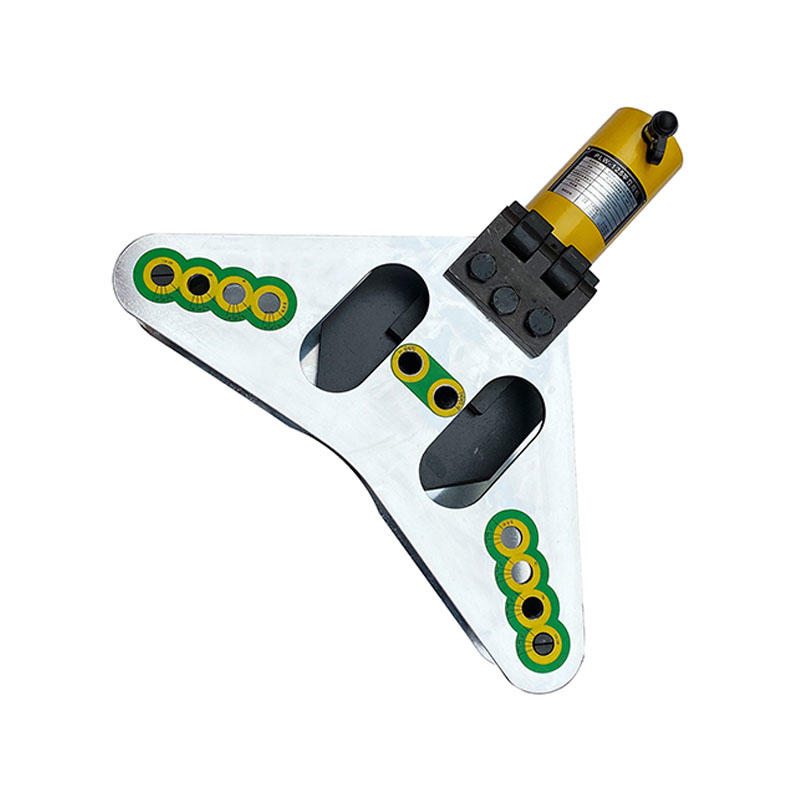

Cheap price battery hydraulic pump wholesaler

Today, with the increasing integration of industrial automation and environmental protection concepts, hydraulic systems, as the heart of industrial equipment, are undergoing a profound change. Among them, the contrast between battery hydraulic pumps and traditional hydraulic pumps not only reflects the direction of technological progress, but also reflects the pursuit of sustainable development. This paper will deeply explore the differences between the two, from five dimensions of power source, efficiency, environmental protection, cost and application scenario for a comprehensive comparative analysis.

Power Sources and modes of Operation: The transition from fossil fuels to clean energy

Traditional hydraulic pump power from the internal combustion engine or the main engine, through the belt or gear transmission, this dependence on fossil fuels is stable, but accompanied by energy waste and environmental pollution. In contrast, the battery hydraulic pump is powered by a battery and driven by an electric motor, which realizes the cleanliness of the power and starts on demand, significantly improving the energy utilization rate.

Efficiency and Energy consumption: A new chapter in energy saving

Traditional hydraulic pumps keep running without a lot of hydraulic power, which is inefficient and consumes a lot of energy. The battery hydraulic pump is based on the principle of "on-demand start", which is activated only when needed, greatly improving efficiency and reducing energy consumption. Especially in intermittent operation or low load state, the energy-saving advantage of the battery hydraulic pump is more obvious.

Environmental protection: zero emission and silent operation

The operation of traditional hydraulic pumps is accompanied by exhaust emissions and noise pollution, which has adverse effects on the environment. In contrast, the battery hydraulic pump achieves zero emissions and almost silent operation, contributing to the protection of the environment and the reduction of noise pollution. This feature makes it possible for battery hydraulic pumps to be used in sensitive environments or residential areas.

Maintenance and cost: long-term economic considerations

Although the initial investment of traditional hydraulic pumps may be low, their high energy consumption and frequent maintenance needs result in high long-term operating costs. Although the initial cost of the battery hydraulic pump is relatively high, thanks to low energy consumption and less maintenance, its total cost of ownership is lower in the long run. In addition, with the advancement of battery technology and the decline in costs, the cost disadvantage of battery hydraulic pumps is gradually narrowing.

Application scenario

Traditional hydraulic pumps are more suitable for large industrial applications with a stable power supply or for fixed-position heavy machinery. With their portability and flexibility, battery hydraulic pumps offer unique advantages in mobile equipment, emergency equipment, remote control equipment or off-grid operations, such as field construction, rescue operations, agricultural machinery and other fields.

conclusion

In summary, the battery hydraulic pump is gradually replacing the traditional hydraulic pump with its characteristics of cleanliness, efficiency, economy and strong applicability, and has become the preferred solution under the dual needs of industrial automation and environmental protection. However, for the continuous high power output needs, the traditional hydraulic pump still has its irreplaceable status. Therefore, the choice of which type of hydraulic pump, should be a comprehensive consideration of the specific application scenarios, environmental conditions and economic benefits, in order to achieve the harmonious coexistence of technological progress and sustainable development.

Español

Español русский

русский