Versatility of Hydraulic Angle Steel Cutters in Cutting Stainless Steel and Special Materials

2025.03.21

2025.03.21

Industry News

Industry News

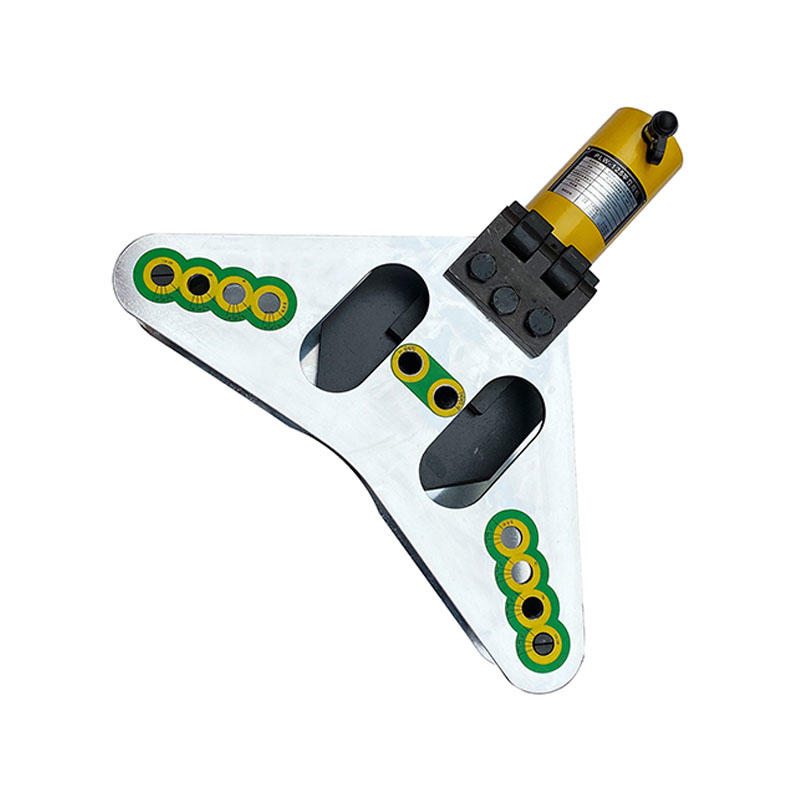

OEM Hydraulic Angle Steel Cutter Tool Exporter in China

The versatility of cutting tools is a crucial consideration for metalworkers, particularly when dealing with a variety of materials. The Hydraulic Angle Steel Cutter has gained significant attention due to its potential to cut through a range of materials with precision. This article will explore whether Hydraulic Angle Steel Cutters are suitable for cutting stainless steel and other special materials, assessing their capabilities and limitations.

Stainless steel, known for its corrosion resistance and durability, presents a challenge for many cutting tools due to its hardness. However, Hydraulic Angle Steel Cutters, with their robust hydraulic systems, are designed to handle such materials. The hydraulic pressure generated by these Hydraulic Angle Steel Cutters allows for a clean and precise cut, even through tough metals, including stainless steel. The high pressure ensures that the blade's edge remains sharp and effective, even when cutting through materials that are known to be abrasive or hard.

In addition to stainless steel, Hydraulic Angle Steel Cutters are also capable of cutting other special materials such as aluminum alloys, titanium, and even some plastics. The adaptability of these Hydraulic Angle Steel Cutters is due to the adjustable pressure settings that can be tailored to the specific material being cut. This feature allows metalworkers to achieve suitable cutting results without damaging the material or the blade.

The cutting process with Hydraulic Angle Steel Cutters begins with the application of hydraulic pressure, which is transmitted through the machine's pistons to the cutting blade. This pressure, when properly calibrated, ensures that the blade applies the necessary force to cut through the material without causing deformation. The precision of the cut is further enhanced by the Hydraulic Angle Steel Cutter's stability and the ability to maintain consistent pressure throughout the cutting process.

Moreover, the use of Hydraulic Angle Steel Cutters in cutting special materials is not limited to their physical capabilities. These Hydraulic Angle SteelCutters often come with features that enhance their usability in various applications. For instance, some models are equipped with a cooling system that prevents the blade from overheating, which is particularly important when cutting materials that are sensitive to heat. This feature not only protects the blade but also ensures that the material being cut retains its properties.

However, it is important to note that while Hydraulic Angle Steel Cutters are highly versatile, they are not universally suitable for all materials. Certain materials, such as those with high carbon content, may require specialized blades or cutting techniques to prevent damage. Additionally, the hardness of the material can affect the lifespan of the blade, necessitating regular maintenance and replacement to ensure continued precision.

In conclusion, Hydraulic Angle Steel Cutters demonstrate a good ability to cut through stainless steel and other special materials with precision and efficiency. Their hydraulic design, adjustable pressure settings, and additional features make them a valuable tool in the metalworking industry. However, it is essential for operators to understand the limitations of their specific cutter and to maintain them properly to achieve results when working with a variety of materials.

Español

Español русский

русский