How to Use an Electric Rebar Cutter for Safe and Efficient Cuts?

2024.06.19

2024.06.19

Industry News

Industry News

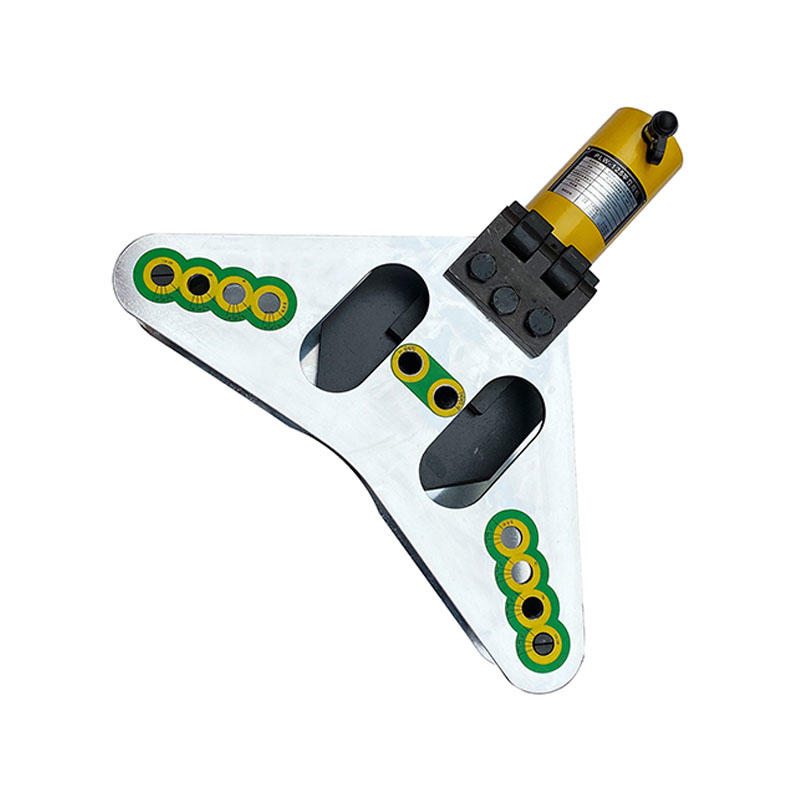

An electric rebar cutter is a powerful tool designed to cut through steel rebar quickly and accurately. Unlike manual cutters, electric rebar cutters use an electric motor to drive the cutting blades, providing consistent force and reducing the physical strain on operators. These cutters are essential in various construction applications, including building foundations, bridges, and other reinforced concrete structures.

Before using an electric rebar cutter, it is essential to ensure that all safety protocols are in place. Manufacturers recommend wearing appropriate personal protective equipment (PPE), such as safety goggles, gloves, and steel-toed boots, to protect against flying debris and accidental injuries. Additionally, checking the electric rebar cutter for any signs of damage or wear is crucial for safe operation. Ensure that the blades are sharp and properly aligned, and inspect the power cord for any frays or cuts.

Position the electric rebar cutter on a stable and flat surface to prevent any movement during operation. Secure the rebar in place using clamps or a vice to ensure it does not shift while cutting. Proper positioning of the rebar cutter and the material will ensure precise cuts and reduce the risk of accidents. Manufacturers recommend adjusting the cutter’s settings according to the thickness of the rebar being cut to achieve good performance.

To use the electric rebar cutter, first, plug it into a reliable power source. Turn on the cutter and allow it to reach full speed before engaging the rebar. Align the rebar with the cutting blades, ensuring that it is positioned correctly for a clean cut. Apply steady pressure to the cutter, allowing the blades to slice through the rebar without forcing the tool. Manufacturers emphasize the importance of letting the electric rebar cutter do the work, as excessive force can damage the tool and compromise safety.

While the primary focus here is on electric rebar cutters, copper pipe bending tools also play a vital role in construction. These tools are used to bend copper pipes into precise angles without compromising the integrity of the material. Proper use of a copper pipe bending tool involves measuring the pipe accurately, marking the bend location, and applying consistent pressure to achieve the desired angle. Using a copper pipe bending tool correctly ensures efficient installation of plumbing systems and other piping applications.

Wire crimping tools are essential for creating secure electrical connections by compressing a connector onto the end of a wire. In construction, wire crimping tools are used extensively for wiring electrical systems, ensuring that connections are strong and reliable. Manufacturers recommend selecting the appropriate wire crimping tool based on the wire gauge and connector type to achieve good results. Proper use of a wire crimping tool involves stripping the wire to the correct length, inserting it into the connector, and applying consistent pressure to crimp it securely.

Safety is paramount when using an electric rebar cutter. Manufacturers highlight several key safety tips to follow:

Always wear PPE: Safety goggles, gloves, and protective footwear are essential.

Inspect the tool: Regularly check the cutter for any signs of wear or damage.

Secure the rebar: Use clamps or a vice to hold the rebar in place.

Maintain a stable position: Ensure the cutter is on a flat, stable surface.

Avoid excessive force: Let the cutter blades do the work to prevent tool damage and injury.

The proper use of an electric rebar cutter is essential for achieving safe and efficient cuts in construction projects. By following manufacturer guidelines and adhering to safety protocols, operators can improve the benefits of these powerful tools. Additionally, integrating copper pipe bending tools and wire crimping tools into construction tasks enhances overall project efficiency and quality.

Español

Español русский

русский