How to Choose the Right Hydraulic Terminal Crimper: 3 Key Points to Consider

2024.11.29

2024.11.29

Industry News

Industry News

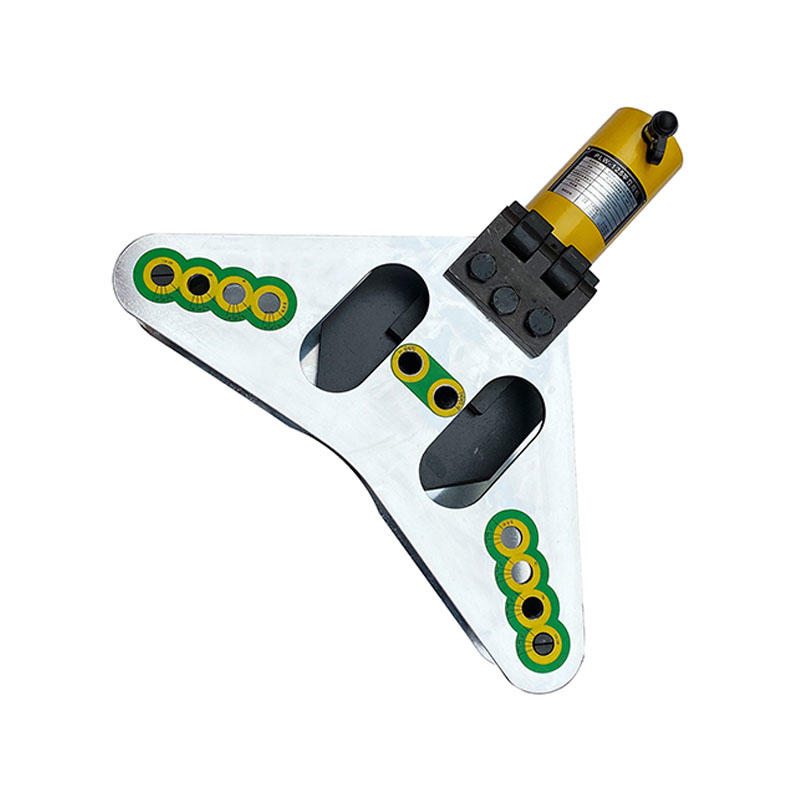

Selecting the right hydraulic terminal crimper is essential for effective, reliable crimping across various applications. From ensuring a secure electrical connection to handling large cables, a good hydraulic crimper makes all the difference. With numerous models available, choosing the one can be challenging. This guide covers three crucial factors—pressure range, compatibility, and ease of use—to help you pick a manual hydraulic hose crimping tool that meets your needs and delivers consistent results.

1. Pressure Range: Ensuring Sufficient Force for the Job

One of the most important factors when selecting a hydraulic terminal crimper is the tool's pressure range. The pressure level of a hydraulic crimper dictates its ability to handle different terminal types and cable sizes. For instance, if you're working with thick cables, you'll need a crimper with a higher pressure range to ensure a secure crimp. Typically, models with pressure ranges from 5 to 16 tons are common, with heavier-duty tasks requiring the upper end of this spectrum.

Consider your main applications and the cable sizes you work with frequently. If you're only working on small or standard-size terminals, a lower pressure range may suffice. However, if your work involves high-resistance connections or thick cables, opt for a manual hydraulic hose crimping tool with a robust pressure capability. Remember, having a tool with more power than you currently need allows flexibility for future projects without sacrificing performance.

2. Compatibility: Selecting the Right Tool for Your Terminals and Cables

Compatibility is key in ensuring that your hydraulic terminal crimper works efficiently across different terminals and cable sizes. Not all crimpers support the same terminal types, so understanding what your work requires will narrow down your choices. Look for a crimper that has adjustable dies or interchangeable heads to accommodate multiple sizes, as this makes the tool more versatile and cost-effective in the long run.

For those who work with a variety of terminals, a manual hydraulic hose crimping tool with multiple die sets is highly beneficial. This feature enables you to adjust for different terminal types, from insulated and non-insulated terminals to heavier-duty lugs. Some hydraulic crimpers come with universal die sets, providing flexibility for various sizes, while others may include specific dies tailored to unique applications. Checking compatibility in advance will help avoid the frustration of finding out that your crimper doesn't fit a particular terminal type.

3. Ease of Use: Prioritizing Efficiency and Comfort

Working with a hydraulic crimper should be a straightforward experience, and ease of use is vital for achieving consistent, high-quality crimps. A hydraulic terminal crimper that's well-designed should feature a comfortable grip and intuitive operation, reducing strain during prolonged use. Look for ergonomic handles and lever mechanisms that allow for smooth crimping with minimal effort, especially if your work involves repetitive tasks.

When evaluating ease of use, consider features like a pressure release valve and precise pressure control, which ensure that the crimp is secure without over-crimping. A manual hydraulic hose crimping tool with a pressure release function allows for quick adjustments and prevents damage to terminals and cables. Additionally, some models come with a built-in gauge that helps you monitor pressure levels, making it easier to apply the right amount of force.

For those new to hydraulic crimping, models with clear setup instructions and calibration guides are helpful. An easy-to-use crimper not only saves time but also improves accuracy and reduces potential errors, which is crucial in applications requiring secure, long-lasting electrical connections.

Additional Considerations for Hydraulic Terminal Crimpers

Aside from these primary factors, there are a few other features to keep in mind when selecting a hydraulic terminal crimper:

Durability: A good crimper should withstand frequent use, so look for models made from high-quality materials like hardened steel or stainless steel. A sturdy construction ensures that the crimper remains effective over time, providing a return on your investment.

Portability: If you work on-site or in different locations, consider the weight and size of the tool. Portable crimpers are designed to be lightweight and often come with carrying cases, making them convenient for professionals who move between job sites.

Maintenance Needs: Hydraulic tools typically require maintenance to keep them functioning optimally. Check if the crimper you're considering has easily accessible parts and if the manufacturer provides maintenance guidelines. Keeping your tool in top shape extends its lifespan and ensures consistent performance.

Español

Español русский

русский