A Step-by-Step Guide to Using a Manual Hydraulic Hose Crimping Tool

2024.06.19

2024.06.19

Industry News

Industry News

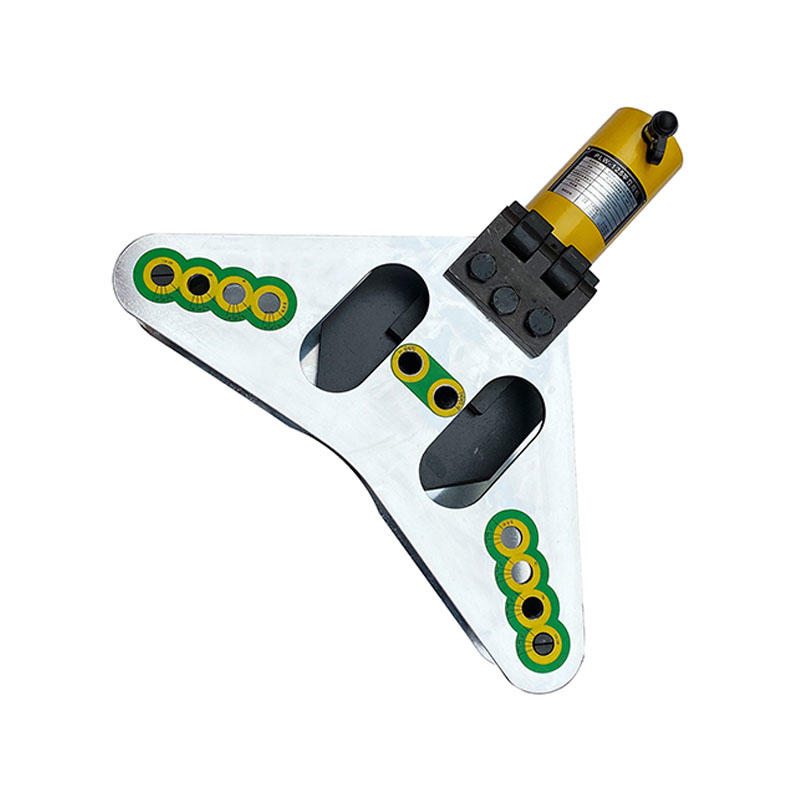

The integrity of hydraulic hoses is paramount to ensure seamless operation and safety. The manual hydraulic hose crimping tool stands as a reliable and cost-effective solution for professionals who require precision and control over the crimping process.

Step 1: Preparing the Hydraulic Hose

Before you begin the crimping process, it is essential to prepare the hydraulic hose. This involves measuring the hose to the required length and ensuring it is free from any kinks or damage. The manual hydraulic hose crimping tool is designed to accommodate various hose sizes, making it versatile for different applications.

Step 2: Selecting the Correct Crimping Die

The manual hydraulic hose crimping machine comes with a set of dies that correspond to different hose sizes. It is crucial to select the appropriate die for the hose you are working with. This ensures that the crimping process is precise and that the hose end fitting is securely attached.

Step 3: Assembling the Crimping Tool

To begin the crimping process, assemble the manual hydraulic hose crimping tool by attaching the selected die to the tool's head. Ensure that the die is securely fastened to prevent any misalignment during the crimping process.

Step 4: Inserting the Hydraulic Hose and Fitting

With the die in place, insert the hydraulic hose into the fitting and then into the die. The hand operated crimping machine allows for manual adjustments to ensure the hose is properly aligned with the fitting.

Step 5: Crimping the Hydraulic Hose

Once the hose and fitting are in place, use the manual hydraulic hose crimping tool to apply pressure. The hand operated crimping machine's lever system allows for controlled and even pressure distribution, which is vital for a secure crimp.

Step 6: Inspecting the Crimp

After crimping, it is essential to inspect the crimp for quality. Look for uniformity in the crimp pattern and ensure there are no gaps or loose areas. The manual hydraulic hose crimping machine's precision helps achieve a consistent crimp every time.

Step 7: Repeating the Process

For multiple hoses or different hose sizes, repeat the process with the appropriate dies and adjustments on the manual hydraulic hose crimping tool.

Step 8: Maintaining the Crimping Tool

Proper maintenance of the manual hydraulic hose crimping machine is crucial for its longevity and performance. Clean the tool after each use, lubricate moving parts, and store it in a dry place to prevent rust or damage.

Step 9: Troubleshooting Common Issues

If you encounter issues such as a poor crimp or the tool not applying enough pressure, refer to the manual hydraulic hose crimping tool's user manual for troubleshooting tips. Common solutions include checking for worn parts, ensuring the correct die is used, and verifying that the tool is properly assembled.

Step 10: Advanced Crimping Techniques

For more complex hydraulic systems or specific applications, the manual hydraulic hose crimping machine can be used to perform advanced crimping techniques. This may involve using specialized dies or adjusting the crimping pressure for unique fittings.

Step 11: Safety Precautions

When using the manual hydraulic hose crimping tool, always follow safety guidelines. This includes wearing protective gloves, eyewear, and ensuring the work area is clear of debris or hazards.

The manual hydraulic hose crimping tool is an indispensable piece of equipment for professionals working with hydraulic systems. By following this step-by-step guide, you can ensure that your crimping process is efficient, safe, and results in high-quality connections. Remember, the key to success with any manual hydraulic hose crimping machine or hand operated crimping machine lies in preparation, precision, and proper maintenance.

Español

Español русский

русский